Welcome to Tillobie

Welcome to Tillobie, where innovation meets precision in Vacuum Forming, Plastic Fabrication, CNC Cutting, Acrylic Fabrication and MDF CNC Cutting.

With a commitment to excellence, we pride ourselves on delivering top-notch solutions for a wide range of industries.

Our Expertise

Vacuum Forming

Plastic Fabrication

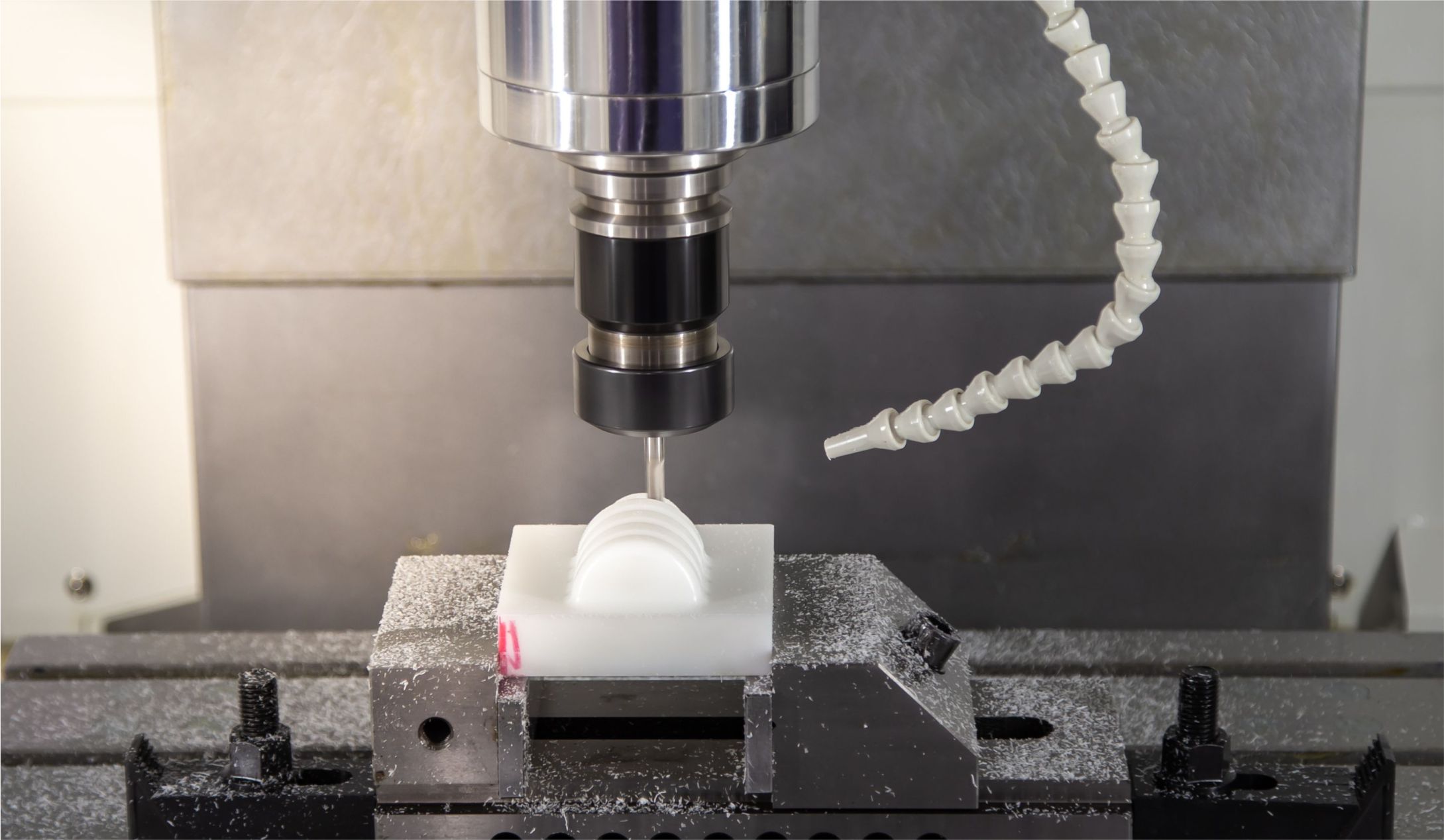

MDF CNC Cutting

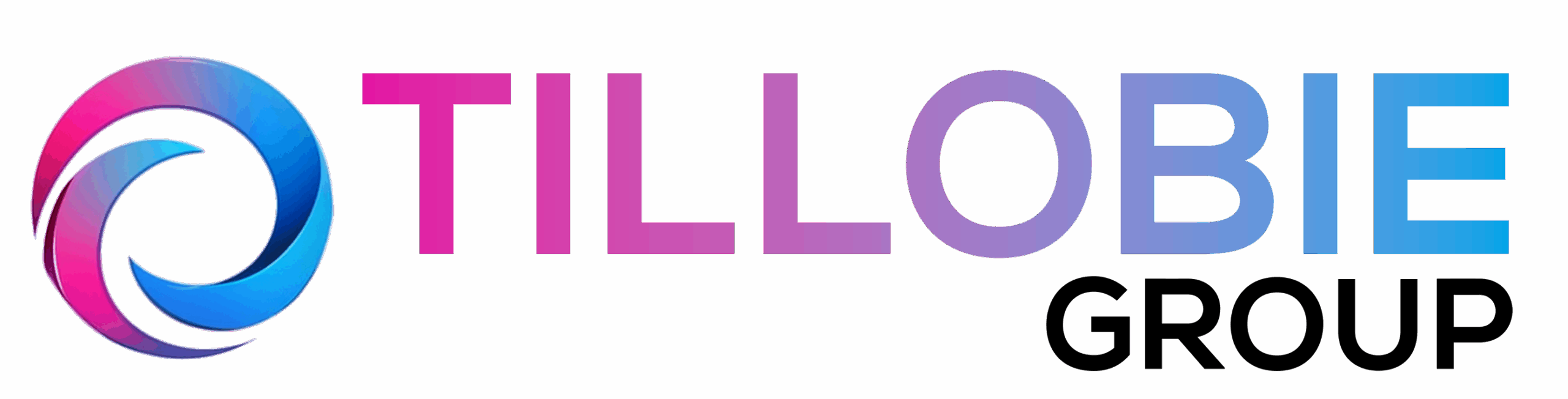

CNC Machining

Why choose Tillobie?

Quality Assurance: Every product undergoes rigorous quality checks to ensure it meets or exceeds industry standards.

Innovation: We thrive on challenges, turning innovative ideas into reality through cutting-edge technology.

Custom Solutions: Tailoring our services to your unique requirements, we offer custom solutions that address your specific needs.

Reliability: With a track record of delivering on time and within budget, you can trust us with your projects.